COATING

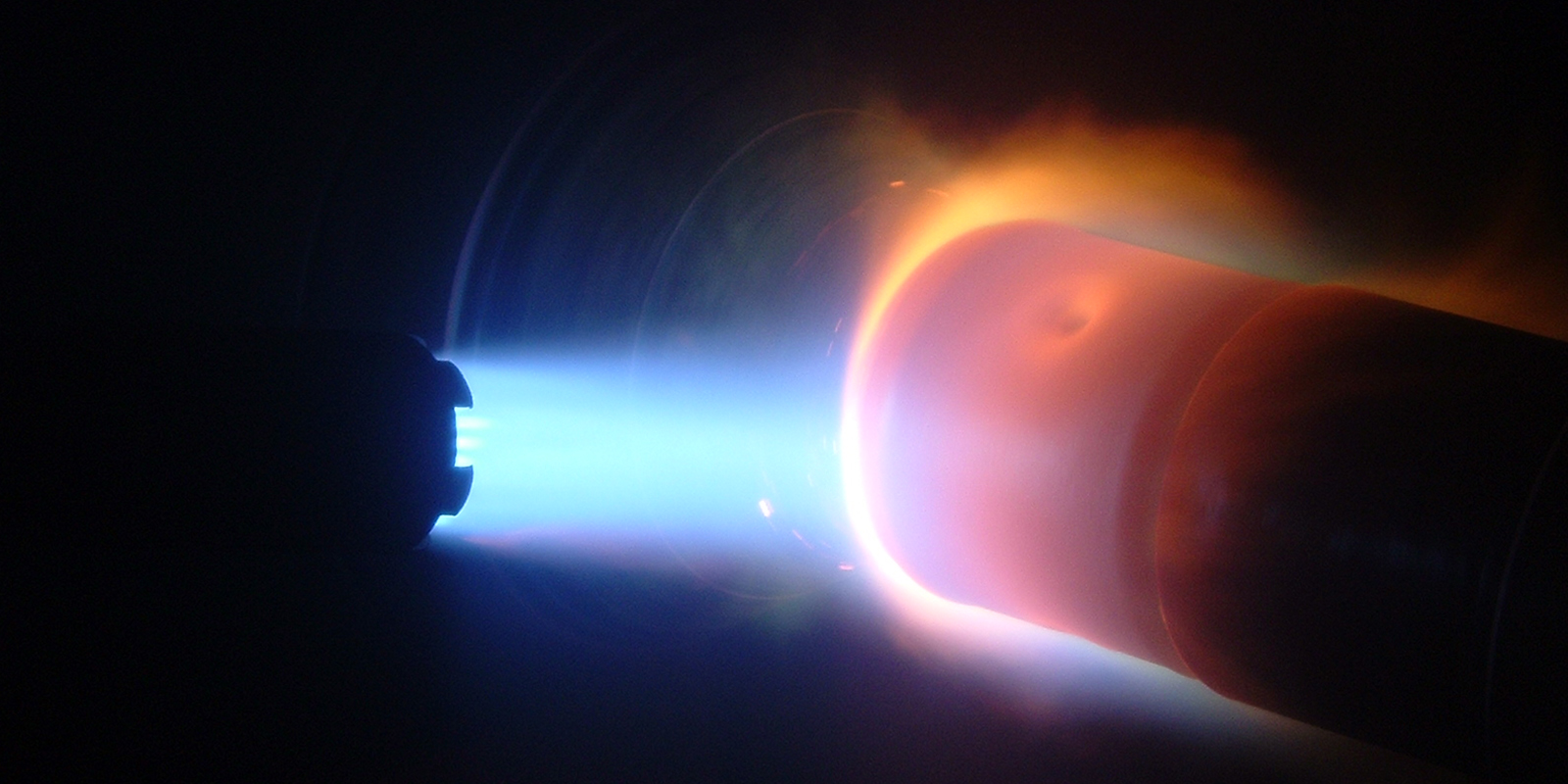

The first step is to understand the problem you are trying to solve. If coating isn’t a good solution for your problem, we will tell you. IF it is then we can help select the right coating.

APPLICATION

There are thousands of incredible coatings on the market today. The rubber meets the road when you design an efficient application method that creates a commercially viable solution.

VALUE

By selecting the right coating and application method we can reduce the time and money it costs to solve heat and corrosion issues.

CASE STUDIES

SAving Robots from corrosion

Thermal oxidation of robotic connections handling parts repetitively at 350C. A need was identifed to insulate the heat transfer from the parts to the robot components reducing the risk of damage to the expensive robots.

200,000 to 1,000,000 miles

When the EPA implemented new emission standards, Cummins, a world-leading manufacturer and distributor of fuel systems and controls, discovered they had a problem.

The JEt-HOT Difference

DISCOVERY THROUGH DIALOGUE

Each of these commercial applications started with a conversation about a specific heat management, corrosion or friction challenge. Our R&D team stepped through the process of vetting possible solutions, scientifically proving Jet-Hot’s capacity to address the issue with precision and durability. With the solution in place, our management team worked with the customer to put together a fulfillment plan that flows seamlessly into the overall production model. The outcome? Jet-Hot takes on the role of operating partner, providing both application and production expertise.

STARTING THE CONVERSATION

As a manufacturer, you don’t have a margin for error. You need someone who can supply real world answers to your application questions. Day after day, Jet-Hot processes thousands of parts across our production facilities in Oklahoma and North Carolina. Our expertise and capacity make us an excellent operating partner for your company.

Want to prolong the life of your parts? Do you have a heat management issue you’d like to discuss? Curious about coatings and how they might apply to your product? To learn more about how Jet-Hot’s ceramic coatings can help you move your project forward...

JET-HOT High-Performance coatings

est. 1982

Today, engineers working through heat management, corrosion protection, and friction reduction issues often start a conversation with Jet-Hot because they’ve tried just about everything else. And what they find is a team of professional problem solvers who sit on their side of the table and look at the challenge from a fresh perspective.

Our chemists and engineers understand the science of coatings, and our manufacturing experts understand the challenges of production, turnaround and cost control. This potent combination has earned Jet-Hot a sterling reputation across multiple commercial markets. You’ll find our coatings at work in a wide range of industries, including automotive, agriculture, transportation, defense, marine, and more.